Fire Escape Rules In South Africa

So, after reading many different articles and doing some intense researching regarding fire escape rules in our beautiful country, I have come up with the following and hope it will somehow assist you, should you catch yourself in a heated situation 😉

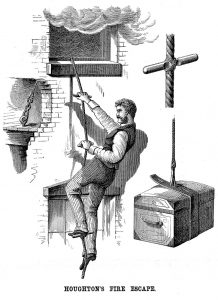

Just a bit of history…Did you know that one of the very first fire escapes was invented in the 18th century in England? David Maseres invented the machine in 1784 called the “Fire Escape”.

This machine was fastened to a window which allowed a person to descend to the ground, as per the below picture.

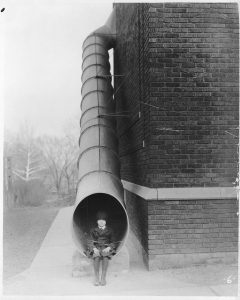

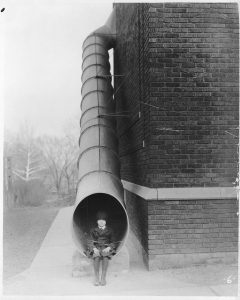

Abraham Wivell then created an improved design, which included an escape chute.

Furthermore, the “Enclosed Tubular Chute Fire Escape” became accepted in schools, hospitals and other institutions in the 1930s. It was a very easy form of escape as people would literally just slide down it.

And as time went by, it evolved and became more modernised, such as a modern type of evacuation slide which is the vertical spiral escape chute and is commonly used for bigger buildings and structures. Buildings are getting taller and new fire escape techniques are developing. Elevators have been thought of as a possible fire escape for high-rise buildings. Further high-rise fire escape methods include parachutes, external collapsible elevators and slides.

Now that we’ve looked at the history and where and when fire escapes came into place, let’s have a look at what it means today.

No one wants to see their house or company go up in flames, therefore there are very strict rules and regulations when it comes to fire safety in South Africa. According to SANS 10400: Part T – the Fire Protection Act says the following: “In order to protect your property and the people in it, South Africa has implemented building regulations to ensure that the buildings are designed, constructed and equipped adequately in the event of a fire”. The Fire Protection Act states the following:

- The occupants of the building, including disabled people will be protected;

- The spread of fire within the building and to other buildings will be minimised;

- Sufficient stability must be insured so there is no major failure of the structural system;

- The spread of smoke shall be controlled and minimised; and

- Adequate means of access for detecting, fighting, controlling and extinguishing shall be provided.

The SANS Act 10400 Part T can be divided into 4 categories:

- Safety Distances;

- Fire Resistance: Relating to building material such as structural walls.

- Requirements for effective fire protection include:

-

- General requirements,

- Regulations relating to safety distances,

- Fire performance

- Fire resistance

- Fire stability of structural elements or components,

- Protection of openings,

- Provision of escape routes,

- Exit doors,

- Feeder routes,

- Emergency routes, dimensions of components of escape routes,

- The width of escape routes,

- Basements,

- Stairways and other changes of level along escape routes,

- Ventilation of stairways in emergency routes,

- Pressurization of emergency routes and components,

- Openings in floors,

- External stairways and passages,

- Marking and signposting,

- Provision of emergency lighting,

- Fire detection and alarm systems,

- Provision and maintenance of firefighting equipment,

- Water reticulation for firefighting purposes,

- Hose reels,

- Hydrants,

- Automatic sprinkler and other fixed extinguishing systems,

- Portable fire extinguishers,

- Mobile fire extinguishers,

- Fire-stopping of inaccessible concealed spaces,

- Protection of services shafts,

- Smoke control,

- Air-conditioning systems and artificial ventilation systems,

- Lift shafts,

- Lifts,

- Firemen’s lift,

- Stretcher lift,

- Access for fire-fighting and rescue purposes

- Rational Designs: Designing of a structure to ensure the level of safety is sufficient by a qualified person.

Now, I think it is very important to have the correct fire safety equipment in your building.

We probably walk pass some of the above items at work every single day and don’t even realise it, but it is vital to know that they are there, where exactly they are and how they are used. It is good to have the necessary equipment to protect the building as well as the people inside it. Therefore, the following equipment will always be helpful:

Alarms – Whether they are heat detectors, smoke alarms or even panic buttons. Heat detectors are generally slower to detect fire than smoke detectors; they are preferably used in smaller spaces where there are higher risks of fire. Smoke alarms are recommended by experts as they detect fires and heat much quicker. Different types of smoke alarms are used such as ionization smoke alarms, which responds to raging fires; photoelectric smoke alarms which respond to a light source; and lastly a combination alarm which is the best recommendation. Ensure that you know where your panic buttons are.

Fire Reels – When outdoors these are generally connected to fire engines or fire hydrants and when inside it is attached the building’s plumbing system.

Fire Extinguishers – Always ensure that you know where these are kept in your workplace as you never know when you might actually have to use one. There are different types of fire extinguishers and the number and type you require would depend on certain circumstances in your building.

Sprinkler Systems – According to Wikipedia, over 40 million sprinkler heads are fitted in buildings each year. Buildings that are completely protected by fire sprinkler systems, over 96% of fire were controlled by fire sprinklers alone. There are different types of sprinklers such as wet pipe systems, dry pipe systems, pre-action, deluge, foam protection, just to name a few.

Fire Exit Signs and Doors – Fire exit signs are a crucial part of an emergency. Proper signage is critical for all fire exits and fire doors. Fire Regulations have stated that fire exits are very clearly marked and should show even when there are power outages.

In the case of an emergency, the last thing you want is for people to run around hysterically. The calmer the people, the calmer the entire situation. Next, let’s have a look at what precautions we can take in the event of a fire:

- Plan your escape plan. Learn your building’s evacuation plan and ensure that fire drills are done regularly;

- Ensure that your building’s evacuation routes are displayed;

- Never lock or block fire exits or doorways, halls or stairways;

- Know the sound of your building’s fire alarm;

- Display emergency numbers near telephones;

- Know where your assembly point is.

In conclusion, ensure that you follow all the rules and regulations required by the government and that your fire equipment and systems are regularly tested and serviced. If you ever do find yourself in a heated situation, always be prepared, react immediately, get out of the building and stay out…

Sources:

sans10400.co.za/fire-protection/

www.fireco-sa.com/south-african-building-regulations-fire-protection.html

https://www.westerncape.gov.za/general-publication/fire-safety-workplace

If you are interested in becoming one of our subscribers, please visit our website.

To view notes with screenshots on how to use our website, please visit our Wiki site.

To view more articles, please visit our blog.

I started at Leads 2 Business in 2023. I worked in the Projects Department as a content researcher for the Northern Cape, Eastern Cape and the Gauteng region. I've experienced many great opportunities for growth and learning in this time. I am now IT Admin Support and I am loving the new ways of contributing to the company's success. My colleagues are always willing to share their knowledge and expertise.