Safety when using heavy machinery

One of the main dangers on the site is the heavy machinery used for various projects. Safely operating these machines is of the utmost importance. Staying calm and alert throughout the day will allow for more productivity and will translate into a positive working environment for all those around you. If you work in construction, you know that working on a construction site can be one of the most dangerous and hazardous jobs out there. Proper safety starts and ends with your decisions and how you conduct yourself.

TRAINING

It is of paramount importance that all operators have identifiable and verifiable training on heavy equipment before operating. Accidents can occur to both the newly trained and seasoned veterans.

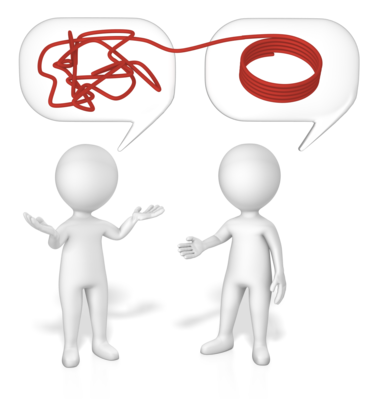

Workers should be trained on the proper procedures to safely operate all pieces of equipment they will be working on. Training should be conducted as a combination of classroom and practical hands-on instruction. Topics that should be covered include safety, hazard identifications, safety features of the equipment and safe manoeuvring of the heavy equipment.

Workers should be trained on how to safely mount and dismount and the proper start up procedure for each piece of equipment. They should have a clear understanding of lifting loads and load capacity for the equipment they will be working on. Retraining and refresher courses should be conducted as needed, especially if a worker is observed operating equipment unsafely or in a manner other than its intended purpose. Only trained workers should be allowed to operate equipment for any reason.

Working with or around heavy equipment should be part of your overall safety program. All workers should be trained on the dangers and hazards of working with heavy equipment. Staying knowledgeable and safe with your equipment is a sure-fire way to make sure you’re protecting yourself and your co-workers.

Conduct a visual inspection before use

Visually inspect heavy equipment before each use to ensure it’s in good operating condition. Equipment must be inspected at least once a day before operating. This must involve walking around with a checklist of components to check for good working order.

LOCK-OUT / TAG-OUT

According to OSHA, employers must train and have procedures in place to ensure that before any employee performs servicing or maintenance on a machine where unexpected start-up or release of stored energy could occur and cause injury, the machine or energy source must be rendered inoperative. This includes hazards such as pinch points, attachments, and raised loads. Picture warnings, locks, and tags must be utilised to prevent any incidents.

LOAD LIMITS

Always be aware of the load limits of varying equipment when operating different machines throughout the day. Depending on the equipment set-up and size the load limits can change. When lifting objects with a machine make sure loads are secure with the proper rigging attachments, and always inspect to ensure they are in good working condition. As with most equipment operations, confirm that all workers are at a safe distance when lifting and moving loads. When loading and unloading equipment at the site, make sure you do it on level ground to avoid rollovers when getting it on or off the truck or trailer.

WALK-AROUND INSPECTION

Equipment must be inspected at least once a day before operating. This must involve walking around with a checklist of components to check for good working order. Hydraulic hoses, undercarriage, oil levels, stress points, etc. are all areas that need to be inspected and reported to the maintenance/safety department before machine start-up. Using a cloud-based mobile device to complete a task such as this can greatly improve communication and response time between operator and mechanic.

BE AWARE OF YOUR SURROUNDINGS

When operating heavy equipment, you need to mindful of the area you are working in and any obstacles you may encounter. Overhead power lines should be deenergized, or if that’s not possible, establish barriers to avoid making contact with them. If digging, make sure that all underground utilities, such as sewer, water, gas and electrical, have been identified and clearly marked to avoid damaging them and creating delays and more work.

Whenever possible, workers should be kept out of areas where heavy equipment is in operating. Operators should be aware of their swing radius, especially when working in tighter spaces, to avoid hitting other workers, bystanders, or other vehicles or equipment in the vicinity.

ENTERING AND EXITING EQUIPMENT

This one should go without saying, but based on the number of injuries workers suffer each year, but there is a right and a wrong way to mount and dismount from heavy equipment. When climbing onto equipment, always maintain three points of contact just like you do when climbing a ladder. Never carry anything with you as you enter or exit.

Never enter or exit equipment that is moving or in operation. Make sure you completely shut off the equipment, engage the parking brake and release any pressure from hydraulic controls. Make sure to take the keys with you to avoid any unauthorized use.

Only use equipment for its intended purpose

Each piece of equipment was designed to perform a specific task. Excavators aren’t cranes and wheel loaders weren’t made to carry workers in the bucket and used as an aerial lift. Pick the right piece of equipment for the task at hand and use it as the manufacturer intended.

Don’t overload or overwork equipment. Be mindful of the payload or lift capacity of the equipment. This may require getting a bigger piece of equipment if what you have isn’t enough to get the job done. If lifting material, make sure all riggings are properly secured. Don’t try to go too fast when operating equipment, especially on slopes.

SLOW IT DOWN

There always are deadlines on any project, which is why you experience stress to get the project done. Unfortunately, one of the largest causes of accidents on construction sites is due to people moving too quickly. Avoiding an injury or accident is as easy as taking your time, and making sure you’re being safe and smart about the machines you’re using.

Sources:

http://www.ehstoday.com/construction/5-tips-safely-operate-heavy-machinery

https://nektardata.com/top-ten-heav y-equipment-safety-tips-for-incident-prevention/

https://www.constructconnect.com/blog/construction-safety/heavy-equipment-construction-safety-tips/

If you are interested in becoming one of our subscribers, please visit our website.

To view notes with screenshots on how to use our website, please visit our Wiki site.

To view more articles, please visit our blog.

About Lola Govender

My name is Lola Govender. I have been working at L2B for 14 years and am very passionate about our business.

Sutton Turner

I am glad you stressed the importance of being trained well on heavy equipment. My brother works with this heavy equipment. Thanks for the tips on using heavy equipment.

Sasha Anderson

Good Day,

Thanks for getting in touch with us. We appreciate your feedback.

Access Doors and Panels

This is a good article. It is a combination of fun and informative. Thanks for sharing this!